Hashem Jahangir1, Mansour Bagheri2*, Seyed Mohammad Javad Daluri3

1- PhD student in structural engineering, Ferdowsi University of Mashhad, Mashhad, Iran

2- Assistant Professor, Faculty of Civil Engineering, Birjand University of Technology, Birjand, Iran

3- Bachelor of Civil Engineering, Faculty of Civil Engineering, Birjand University of Technology, Birjand, Iran

Abstract

Concrete is one of the most commonly used materials in the construction industry, due to the presence of cement as the main part.

It is considered a harmful material for the environment. The cement production process is very energy-intensive and harmful, so that it introduces large amounts of greenhouse gases into the environment. Researchers are trying to introduce a new generation of environmentally friendly concrete by finding methods.

In this article, the ash produced from the cone-shaped fruit of the pine tree has been used as a substitute and reducer of cement consumption in the concrete mixing plan. Since the ash used in this research, in addition to reducing the consumption of cement, prevents the accumulation of pine cones in nature and thus creates environmental pollution, it also reduces the harmful effects of concrete production on the environment.For this purpose, the fruit of the pine tree was collected and burned, and the remaining ash was used. The amount of 20 percent by weight of pine ash in standard cubic and cylindrical samples was used instead of cement and its effect on the compressive strength of the samples was evaluated. Evaluations showed that the use of this amount of pine ash increases the compressive strength of concrete, and therefore, it can be an important step in the direction of optimal utilization of materials and materials that seem useless at first glance.

Estimation of concrete compressive strength by substitution of pinyon pine ash

for cement

Hashem Jahangir1, Mansour Bagheri2*, Seyed Mohammad Javad Delavari3

1

Ph.D. Student of structural engineering, Ferdowsi University of Mashhad, Mashhad, Iran

2

Assistant Professor of civil engineering, Birjand University of Technology, Birjand, Iran

3- Bachelor Student of civil engineering, Birjand University of Technology, Birjand, Iran

ARTICLE INFOABSTRACT

Received: 12/04/2018

Revised: 11/06/2018

Accepted: 07/08/2018

Nowadays, one of the most popular ways to get a more sustainable

cement industry is using additions as cement replacement. However,

there are many civil engineering applications in which the use of

sustainable cements is not extended yet, such as special foundations,

and particularly micro piles, even though the standards do not

restrict the cement type to use. These elements are frequently exposed

to the sulphates present in soils. The purpose of this research is to

study the effects of using pinyon pine ash as a substitution for

ordinary Portland cement and reduce its content in the concrete mix

design. For this reason, 20 % of pinyon pine ash with respect to

cement weight was used and the compressive strength of concrete is

obtained from testing cubic and standard cylinder specimens.

Considering the results obtained, using pinyon pine ash increase the

compressive strength of concrete. On the other hand, more axial

micro cracks were occurred in pinyon included specimens and their

colour were darker comparing to representative specimens without

pinyon pine ash. This study shows that using pinyon pine ash could

be an effective and Eco-friendly alternative for ordinary Portland

cement in industry and construction and could reduce the dangerous

effects of using cement in concrete.

Keywords:

Pinyon Pine ash

Cement

Compressive Strength

Cubic Specimens

Cylinder Specimens

All rights reserved to Iranian Society of Structural Engineering.

doi: 10.22065/jsce. 2018.126900.1517

*Corresponding author: Mansour Bagheri.

Email address: mnsrbagheri@birjandut.ac.ir

1- Introduction

From the past to present, various building materials have been used by humans. Among them, wood, stone, steel, and concrete are the most commonly used building materials. Concrete, which is actually a type of stone made by humans, is one of the most widely used building materials due to its suitable properties. Cement, as the main component of concrete, is considered a strategic material and is being produced significantly. However, cement is considered an environmentally harmful material due to its energy-intensive and pollutant-producing production process. According to the statistics of the Portland Cement Association, 8.3 billion cubic meters of cement are produced annually, resulting in approximately 1.35 million tons of carbon dioxide (CO2), nitrogen oxides (NOx), and sulfur oxides (SOx) being emitted into the environment. The presence of this amount of CO2 in the environment leads to an increase in temperature, greenhouse gas emissions, and ultimately climate change. Since concrete is one of the most commonly used building materials in the construction industry, researchers are looking for ways to reduce the use of mineral materials in concrete. The high cost of mineral materials and environmental considerations compared to waste disposal of natural resources has forced researchers to find the most optimal methods for the construction and concrete industry.

In recent years, a new generation of environmentally friendly concretes has been introduced and their efficiency has been evaluated. The use of waste and recycled materials in concrete production has become a common practice. Concrete production using pozzolanic materials, silica fume, nano-silica, volcanic ash, and various types of ashes is one of the proposed solutions to reduce cement consumption in concrete structures.

Today, the use of low-calcium fly ash has received much attention from researchers. Using this type of ash can reduce cement consumption in concrete without any changes in its mechanical and compressive strength properties. Pine cone tree cones are considered harmful to the environment, but by burning them, low-calcium ash can be produced. This ash has pozzolanic properties and can increase the rate of cement hydration. Given the abundance of pine trees in Iran and the environmental harm caused by their cones, this article evaluates the effectiveness of using pine cone ash as a substitute for cement in concrete.

2- Specifications of Used Materials

In this section, the properties of each material used in the mix design of standard cubic and cylindrical samples are introduced.

2-1- Cement

Cement is an adhesive material that has the ability to bond particles together and form a cohesive body. Cement accounts for 10 to 12 percent of the volume of concrete. Cement is made by combining lime, silica, clay, and mineral oxides at a temperature of 1400 to 1500 degrees Celsius. According to the technical regulations and standards of irrigation and drainage networks, except in cases where otherwise specified in the technical specifications, the type of cement used for preparing concrete should be Portland Type 2 or 5 cement. The cement used in this article is East Type 2 cement, and its properties are listed in Table 1.

2-2- Aggregates

Coarse aggregates are divided into two categories: sand and gravel. Aggregates make up about 66 to 75 percent of the volume of concrete. The aggregates used in this article were obtained from the Khorasan Concrete Foundation Company. A sample of these aggregates is shown in Figure 1, which will be discussed in the second section.

2-3- Water

Impurities present in water may affect the setting of cement and the strength of concrete. In most standards, suitable water for concrete is water that is suitable for drinking. As a general rule, any water with a pH between 6 and 8 and no salty taste can be used for concrete. Generally, water that is suitable for concrete will also be desirable for its processing. It is generally recommended that water used for concrete processing be free of anything that may affect the hardened concrete.

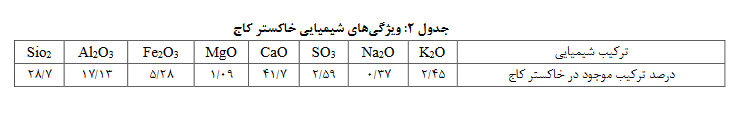

2-4- Pine Cone Ash

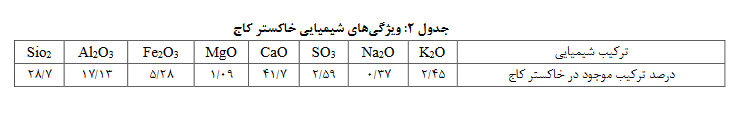

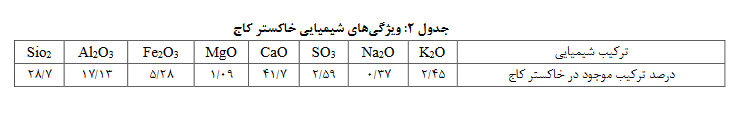

In this article, to obtain ash from pine cone fruits, some of them were collected first. Then, with safety precautions, these dried fruits were burned in enclosed ovens at a temperature of about 350 degrees Celsius, and the resulting ash from combustion was used. After cooling down the collected ashes, they were milled to remove any possible impurities and added to the concrete mix. Table 2 reports the chemical properties of pine cone ash.

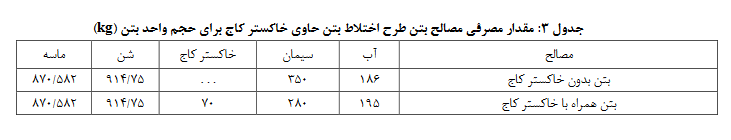

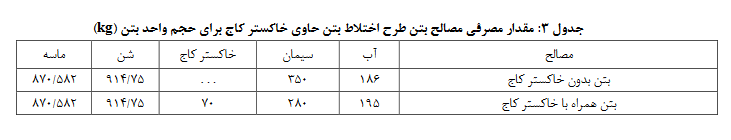

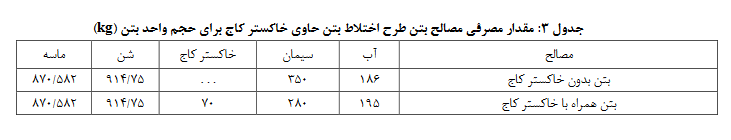

3-Mixing plan

By providing the required materials, including cement, water, stone materials and pine cone ash, and according to the amount of consumption of each of them per concrete volume unit according to table 3, the required schedule for concrete pouring was done. The number of samples considered in this article is two cubic samples and two standard cylindrical samples [4].

After calculating the consumption amount of each of the materials required for pouring concrete, the amount of cement, water and stone materials are weighed and separated separately. To prepare the ash of pine cones, before weighing, they are ground to remove the possible impurities in them and a homogeneous concrete mixture is the result. Figure 1 shows the stages of preparing the materials needed in the concrete mixture.

4- Compressive strength tests

In this article, two 15cm x 15cm x 15cm cubic samples and two 15cm x 30cm cylindrical samples were made for each of the concrete mixing design modes without pine cone ash and with pine cone ash. These samples were kept in a water tank for 28 days.

Figure 2 and Figure 3 respectively show the samples after pouring concrete and how they are placed in the water basin.

After 28 days of processing, the samples were placed under a jack to determine the compressive strength. In the compressive strength test, the cubes were placed in the compression machine in such a way that the two opposite surfaces, which were adjacent to the mold during concrete pouring, were in contact with the upper stirrup.

and be placed under the device. In other words, the position of the cube during the test is perpendicular to its position when pouring concrete into the mold

Figure 4 and Figure 5 respectively show the placement of cubic samples in two states without ash (control samples) and with pine ash, and Figure 6 and Figure 7 respectively show the placement of control cylindrical samples with pine ash under the compressive strength test jack.

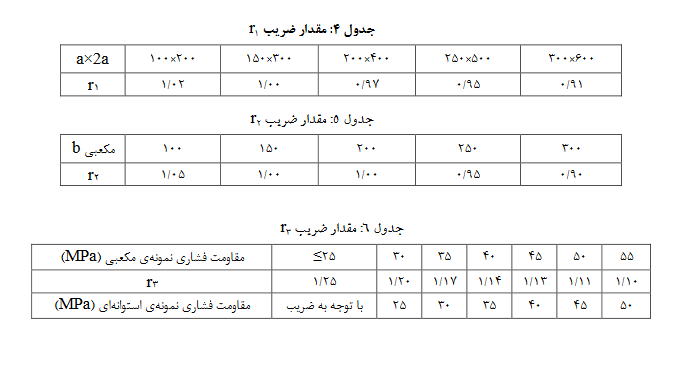

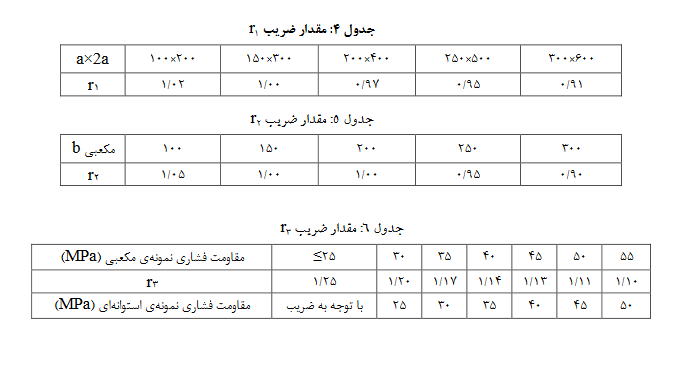

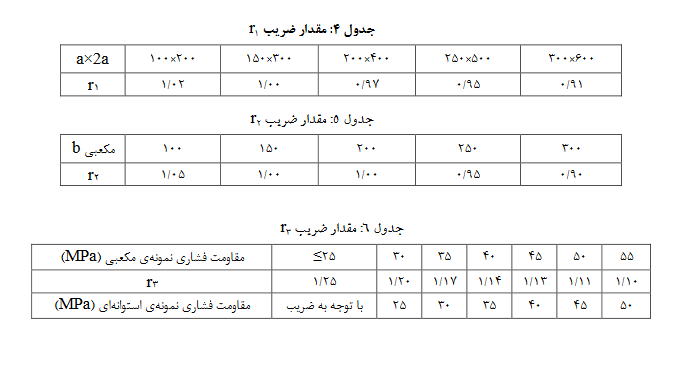

According to the ninth topic of the National Building Regulations, a standard example is a sample of cylinders with dimensions of 300 mm x 150 mm. In case of using cubic samples, their resistance should be converted to the same resistance as a standard cylindrical sample. For this conversion, from the coefficients 1r (the coefficient of conversion of the sample resistance of standard cylinders to the sample resistance of non-standard cylinders), 2r (the coefficient of conversion of the resistance of a cubic sample with dimensions of 200 mm to the same resistance as a cubic sample with dimensions other than 200 mm) and 3r (the coefficient of conversion of the sample resistance of standard cylinders to the resistance of A cubic sample with dimensions of 200 mm according to Table 4, Table 5 and Table 6 is used.

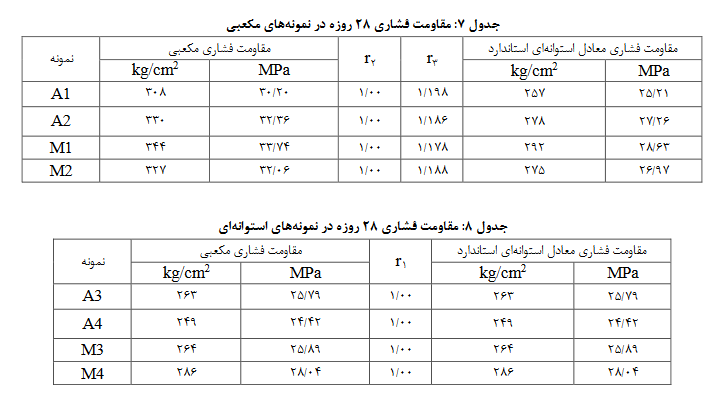

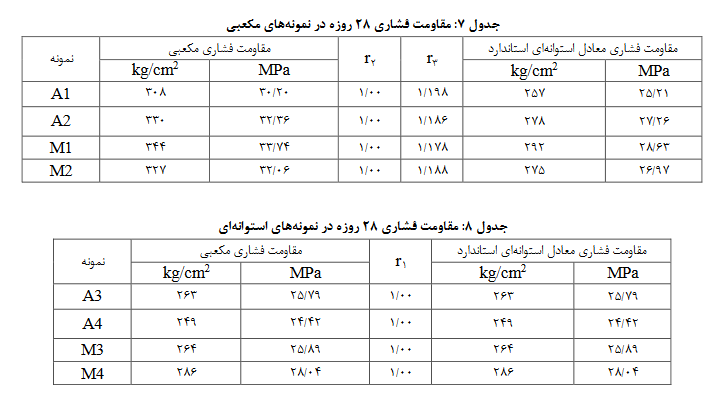

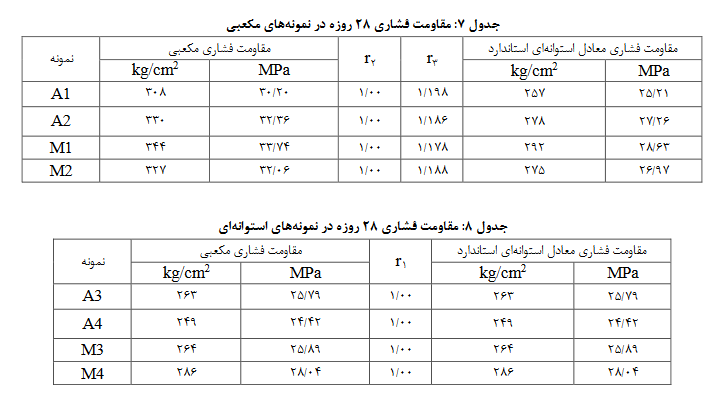

The results of compressive tests and equivalent compressive strength of standard cylinders in two cases without pine ash (control samples) and with pine ash for cubic samples and improved cylinders are reported in Table 7 and Table 8, respectively, in units of 2 kg/cm and MPa.

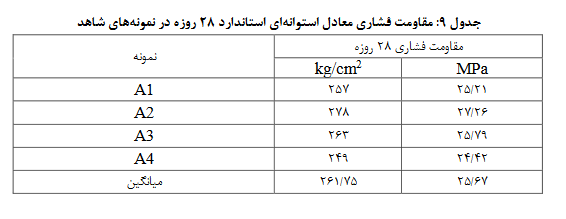

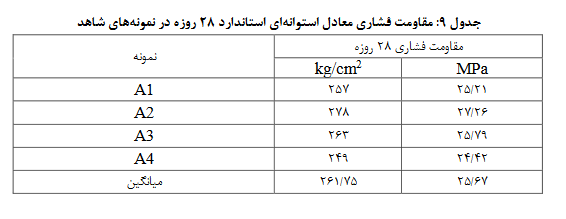

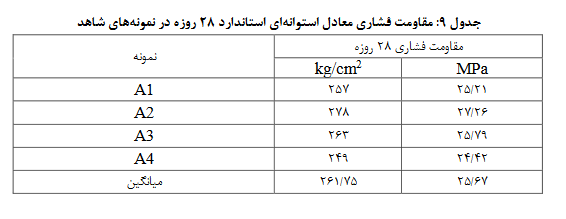

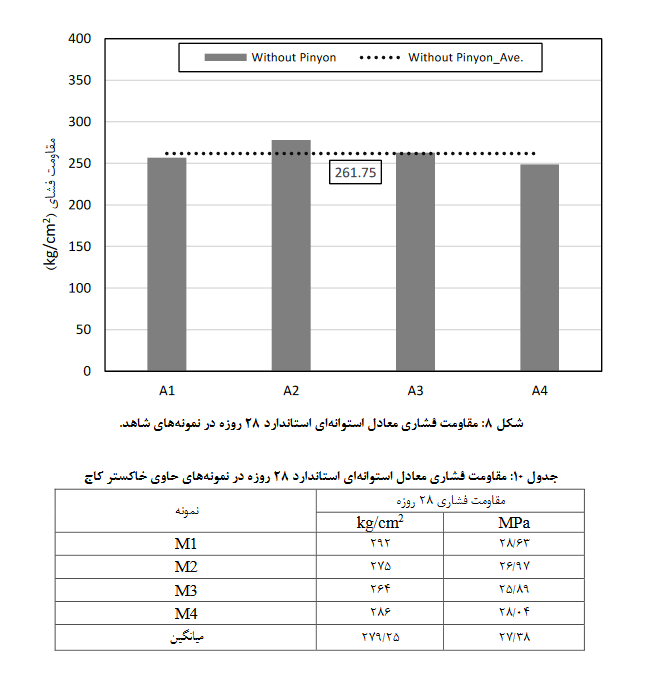

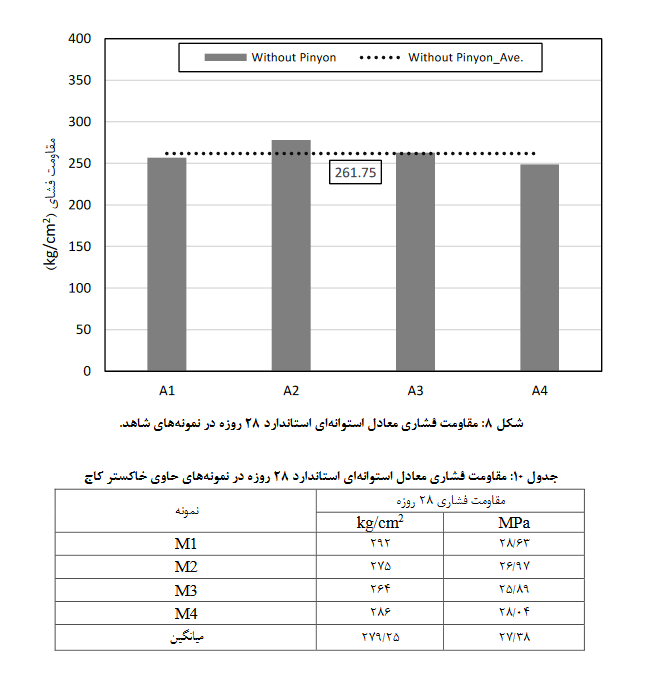

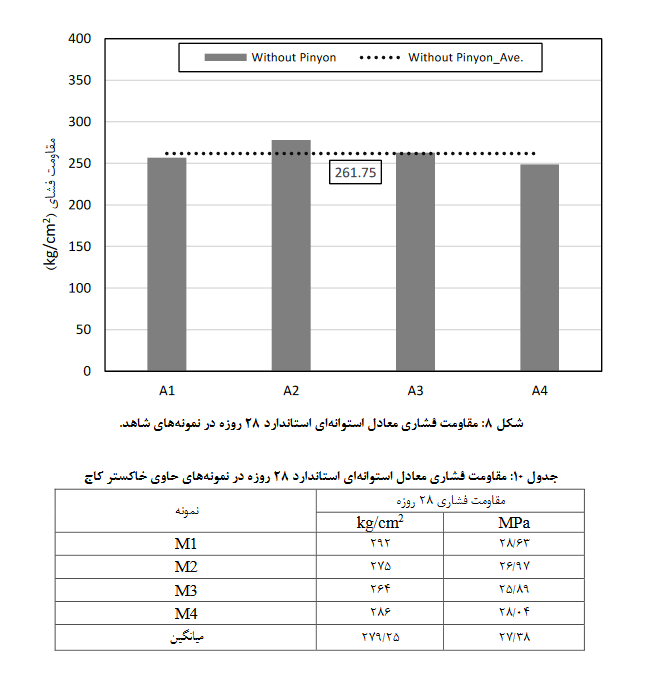

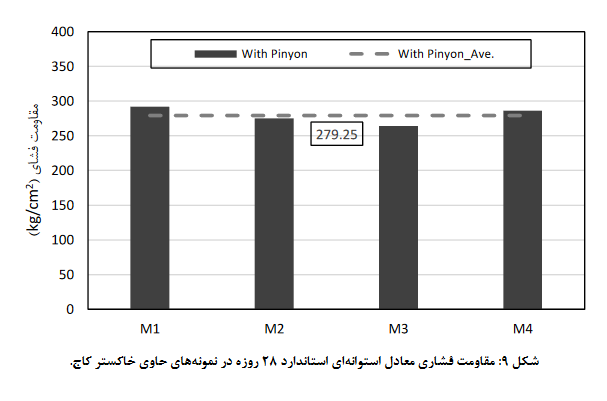

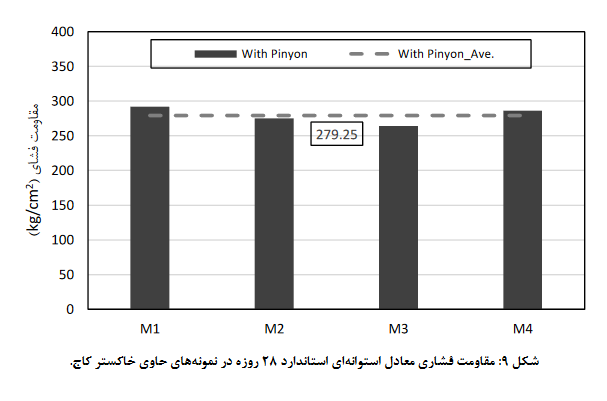

As can be seen in Table 7, since the cubic samples have a size of 150 x 150 mm, the R2 coefficient is equal to 1.00 according to Table 5 and the value of R3 coefficient has been calculated by interpolating the reported values in Table 6. Considering that the samples of the cylinders are 300 mm x 150 mm, the value of coefficient r1 in table 8, according to table 4, is considered equal to 1.00. The equivalent compressive strength of standard cylinders along with their average in control samples are reported in Table 9 and Figure 8 and in samples with pine ash in Table 10 and Figure 9.

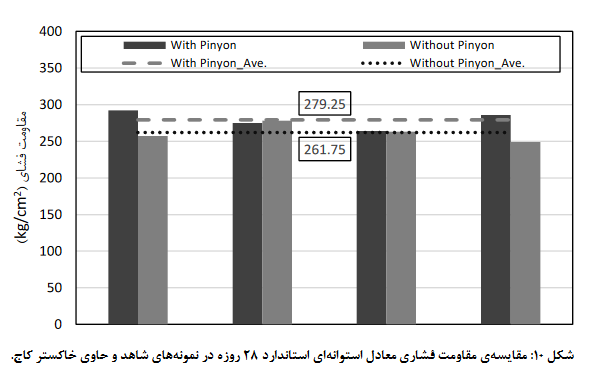

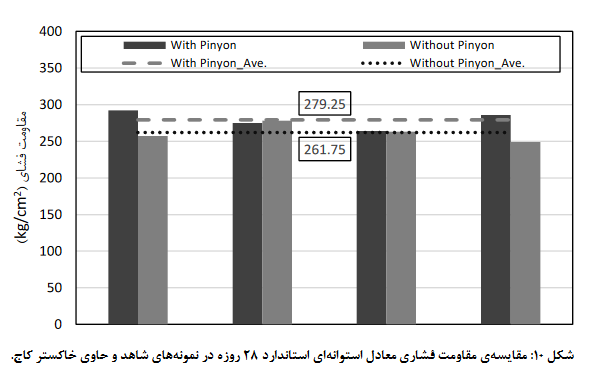

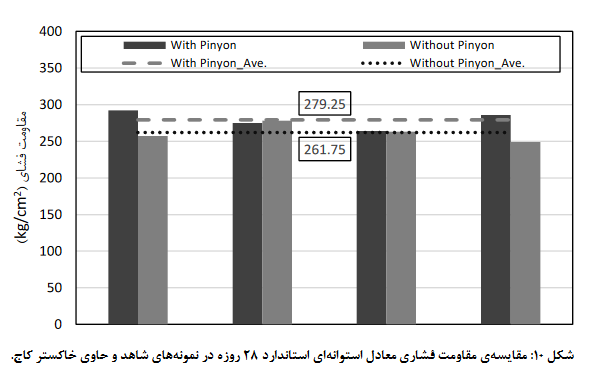

In order to make a more accurate comparison, the equivalent compressive strength of standard cylinders in control samples and samples with pine cone ash is shown in Figure 10.

As can be seen in Figure 10, the average compressive strength of the standard cylinders for the control samples is equal

261/75/2 kg/cm (25/67 MPa) and in samples with pine ash it is 279/279/2 kg/cm (27/38 MPa). Therefore, by replacing 20% by weight of pine cone ash as a substitute for cement in concrete samples, the compressive strength has increased by 6.68%. In the following, how the cube samples break in two cases without pine ash (control samples) and with better quality pine cone ash is shown in Figure 11 and Figure 12.

The failure of cylindrical samples in two cases without pine ash (samples containing control ash) and better quality pine cones in

Figure 13 and Figure 14 are shown.

The comparison of Figures 11 and 12, as well as Figures 13 and 14, shows that the samples containing pine cone ash have a higher axial shrinkage and a darker color compared to the samples without pine cone ash. On the other hand, the results indicate that this type of concrete sets faster when mixed.

In this article, an attempt was made to reduce the amount of cement used in concrete mixtures by using ash from pine cone fruits. Since the ash used in this study not only reduces cement consumption but also prevents pine cone accumulation in nature and consequently reduces environmental pollution, it also reduces the negative environmental effects of concrete production. The results showed that samples containing 20% pine cone ash had an average compressive strength of 27.9 MPa (38.27 kg/cm2) at 28 days, which is equivalent to a 6.68% increase compared to samples without pine cone ash (control samples) with an average compressive strength of 25.61 MPa (35.75 kg/cm2). The examination of sample fractures showed that axial cracks were more frequent in samples containing pine cone ash than in control samples. Additionally, the results showed that the use of pine cone ash changes the color of concrete and causes cement paste to set faster. Therefore, these materials can be used as a suitable substitute for cement in concrete and prevent environmental destruction and greenhouse gas emissions caused by cement production.

References.

1] Mathur VK. (2006) Composite materials from local resources. Constr Build Mater; 20: 470–477.

[2] Salem ZTA, Khedawi TS, Baker MB, et al. Effect of Waste Glass on Properties of Asphalt Concrete Mixtures. Jordan J

Civ Eng; 11.

[3] Cartuxo F, de Brito J, Evangelista L, et al. (2016) Increased durability of concrete made with fine recycled concrete

aggregates using superplasticizers. Materials (Basel); 9: 98.

[4] Andreu G, Miren E. (2014) Experimental analysis of properties of high performance recycled aggregate concrete. Constr

Build Mater; 52: 227–235.

[5] Bjork F. (1999) Concrete Technology and Sustainable Development. In: CANMET/ACI International Symposium on

Concrete Technology for Sustainable Development.

[6] Aitcin P-C. (2000) Cements of yesterday and today: concrete of tomorrow. Cem Concr Res; 30: 1349–1359.

[7] Berndt ML. (2009) Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr

Build Mater; 23: 2606–2613.

[8] Jayapalan AR, Lee BY, Kurtis KE. (2013) Can nanotechnology be green? Comparing efficacy of nano and microparticles

in cementitious materials. Cem Concr Compos; 36: 16–24.

[9] D’Alessandro A, Fabiani C, Pisello AL, et al. (2016) Innovative concretes for low-carbon constructions: a review. Int J

Low-Carbon Technol; 12: 289–309.

[10] Liew KM, Sojobi AO, Zhang LW. (2017) Green concrete: Prospects and challenges. Constr Build Mater; 156: 1063–

1095.

[11] Lothenbach B, Scrivener K, Hooton RD. (2011) Supplementary cementitious materials. Cem Concr Res; 41: 1244–1256.

[12] Wu M, Li C, Yao W. (2017) Gel/space ratio evolution in ternary composite system consisting of Portland Cement, silica

fume, and fly ash. Materials (Basel); 10: 59.

[13] Zhang P, Wan J, Wang K, et al. (2017) Influence of nano-SiO2 on properties of fresh and hardened high performance

concrete: A state-of-the-art review. Constr Build Mater; 148: 648–658.

[14] Ortega JM, Esteban MD, Rodriguez RR, et al. (2017) Long-Term Behaviour of fly ash and slag cement grouts for

micropiles exposed to a sulphate aggressive medium. Materials (Basel); 10: 598.

[15] Velázquez S, Monzó JM, Borrachero M V, et al. (2014) Assessment of pozzolanic activity using methods based on the

measurement of electrical conductivity of suspensions of Portland Cement and pozzolan. Materials (Basel); 7: 7533–7547.

[16] Marks Michałand Glinicki M, Gibas K. (2015) Prediction of the Chloride Resistance of Concrete Modified with High

Calcium Fly Ash Using Machine Learning. Materials (Basel); 8: 8714–8727.

[17] Kalaw ME, Culaba A, Hinode H, et al. (2016) Optimizing and characterizing geopolymers from ternary blend of

Philippine coal fly ash, coal bottom ash and rice hull ash. Materials (Basel); 9: 580.

صاحب امتیازانجمن مهندسی سازه ایران

19 نشریهعلمی–پژوهشیمهندسی سازه و ساخت، دوره5، شمارهویژه2، سال1397،صفحه5تا19

[18] Xu W, Lo TY, Wang W, et al. (2016) Pozzolanic reactivity of silica fume and ground rice husk ash as reactive silica in

a cementitious system: A comparative study. Materials (Basel); 9: 146.

[19] Aprianti E. (2017) A huge number of artificial waste material can be supplementary cementitious material (SCM) for

concrete production–a review part II. J Clean Prod; 142: 4178–4194.

[20] Hemalatha T, Ramaswamy A. (2017) A review on fly ash characteristics–Towards promoting high volume utilization in

developing sustainable concrete. J Clean Prod; 147: 546–559.

[21] Norhasri MSM, Hamidah MS, Fadzil AM. (2017) Applications of using nano material in concrete: A review. Constr

Build Mater; 133: 91–97.

[22] Khatib JM, Negim EM, Sohl HS, et al. (2012) Glass powder utilisation in concrete production. Eur J Appl Sci; 4: 173–

176.

[23] Pereira P, Evangelista L, De Brito J. (2012) The effect of superplasticisers on the workability and compressive strength

of concrete made with fine recycled concrete aggregates. Constr Build Mater; 28: 722–729.

[24] Saikia N, de Brito J. (2014) Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle

waste as a partial substitution of natural aggregate. Constr Build Mater; 52: 236–244.

[25] Ismail S, Ramli M. (2013) Engineering properties of treated recycled concrete aggregate (RCA) for structural

applications. Constr Build Mater; 44: 464–476.

[26] Topcu IB, Canbaz M. (2004) Properties of concrete containing waste glass. Cem Concr Res; 34: 267–274.